A step-by-step demonstration of how to calibrate a Fluid Filled Pressure Transducer using a Pressure Gauge Kit.

Equipment required

- A Fluid-Filled Physiological Pressure Transducer (includes clip-on dome)

- Pressure Gauge Kit (includes syringes, tubing, and a manometer dial)

- Warm saline

- Interface Cable

- Bridge Amp

- PowerLab

- Computer with LabChart Software installed

Procedure

Equipment set-up

Before recording any signals, it’s important to set up your data acquisition equipment correctly.

- Attach the three-way tap to the dome of the Pressure Transducer.

- Connect the Pressure Transducer to the Bridge Amp using the Interface Cable.

- Connect the Bridge Amp to the PowerLab.

- Lastly, connect the PowerLab to your computer and open LabChart.

Fill the transducer dome with warm saline

Before you can begin recording, the transducers’ clip-on dome needs to be filled with warm saline. To do this:

- Fill a syringe with warm saline.

- Connect the syringe to the three-way tap.

- Open the tap to the dome and slowly introduce the saline until it’s full.

Tip: Fill all the way to the top, as the filled catheter attaches to this end and you don't want any air bubbles.

- Once filled, close off the tap and remove the syringe.

- Attach the fluid-filled dome to the transducer. Now you are ready to zero the transducer.

Zeroing the transducer

- In LabChart, click on the channel that the Bridge Amp is connected to and select ‘Bridge Amp’ from the drop-down menu.

- In the Bridge Amp Dialog make sure that the range is sufficient for the pressures you are recording. In this case, 10mV will be fine.

Tip: Care must be taken when determining an appropriate range for your pressure transducer. If the range is too large, the resolution will be poor and small fluctuations will not be seen. Conversely, if the range is too small, the signal will go out of range and you will lose data. Most transducers (on 10 V excitation) have an output of ~ 5 mV/100 mmHg.

- Next, zero the transducer by clicking ‘Zero’. This will take a couple of seconds, make sure that the transducer is not moved during this period.

- Once that is done, click ‘OK’.

Calibrating the transducer

Once the transducer has been zeroed, you are now ready to calibrate the transducer. This is done by recording two pressures of known value (using the pressure gauge) and using these known values to calibrate the transducer

- First, start the recording by clicking the ‘Start’ button.

- Because the transducer has been zeroed and is open to the air, the reading on-screen should read zero. Add a comment here labeled ‘0’.

- Connect the Pressure Gauge to the other side of the transducer and slowly increase the pressure to 100. You should see the dial on the manometer go up.

- Add another comment at this new pressure reading labeled ‘100’.

- Click ‘Stop’ to stop the recording.

Units Conversion

- Make a selection of the recording between the two comments by clicking and dragging the mouse across the recording.

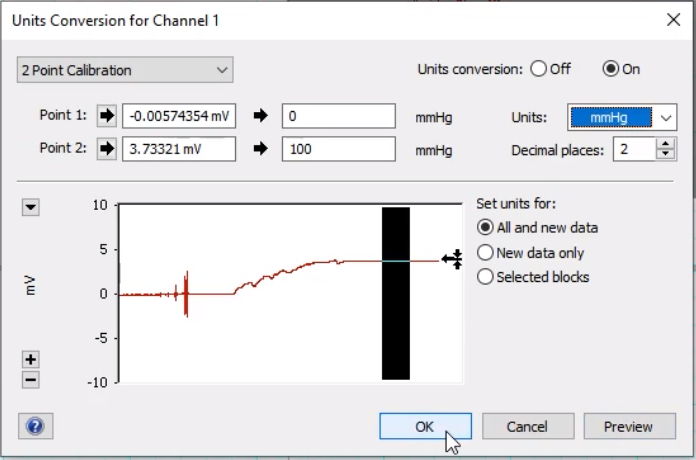

- Click on the Channel name and go to ‘Units Conversion'. The Units Conversion Dialog will display the recording that was selected (see image below).

- Select an area of the recording that represents the first pressure reading of 0 mmHg in the preview window.

- Then click the arrow next to Point 1 and the voltage for that pressure will be entered into the left-hand box.

- Next, type in the pressure value this selection represents in the right-hand box (in this case, 0).

- Repeat the above steps for the second pressure recording of 100, for Point 2.

- Make sure the units are set as mmHg, then click ‘OK’

- You now have a calibrated transducer!

Additional Resources:

How to Calibrate a Fluid Filled Transducer Using the DeltaCal Electronic Pressure Simulator »